Cyclone

When performance is paramount

Typical Applications

- Rapid temperature cycling to thermally stress materials and components

- Burn-in and life testing of electronic components (including powered cycling)

- Temperature/humidity testing under fixed or cyclic conditions, satisfying numerous IEC 60068 test requirements plus a wide range of equivalent specifications

SIMPLEtouch

Touch Screen Programmer

Easy set-up and monitoring of chamber conditions, simplifies programming of complex cycles… read more

| Benefit | Achieved by |

|---|---|

| High performance | Laminar air flow from left to right across the internal space – maintains uniform temperature at all locations even with high packing density |

| PT100 sensor for stable and reliable temperature measurement | |

| Capacitive humidity sensor gives optimum combination of accuracy, rapid response and reliability | |

| Chambers built from high quality components ensuring long service lifetimes | |

| Customisable | Wide range of volumes available (216 to 3000 litres) |

| Environmental control systems can be tailored to meet minimum temperature, cooling rates and relative humidity requirements | |

| Labview-based user interface developed by Sharetree and easy to upgrade and customise | |

| Models available that combine vibration and temperature testing | |

| Cooling plants located remotely from chamber if preferred to reduce noise and heat; quieter water-cooled option available if site has chilled water supply | |

| Extensive list of options and customisations | |

| Easy to use and maintain | Factory-calibrated and expertly installed for you by Sharetree |

| Uses readily available components | |

| PC-based touchscreen control panel – connects to industry standard PID controller that is readily maintained or replaced, minimising downtime |

| Temperature Uniformity and Stability Specifications* (all models) | ||

|---|---|---|

| Thermal Gradient (<100°C) | ± 2 | °C |

| Thermal Gradient (>100°C) | ± 2 | % of temperature |

| Temperature Fluctuation | ± 0.3 | °C |

| *Measured after stabilisation (IEC 60068-3-5) | ||

Cyclone Thermal Chambers

Choose from three different cooling mechanisms depending on your requirements.

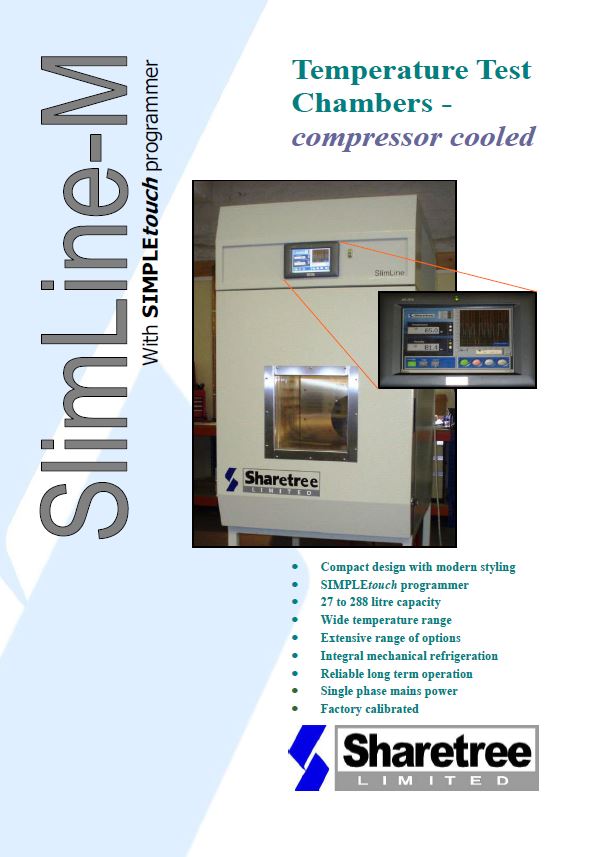

Compressor Cooling

- Refrigerant gases in a closed-loop system are repeatedly compressed and expanded to cool the air in the chamber (same principle as domestic refrigerators)

- Maximum temperature = +180°C; minimum temperature = -40°C (single-stage compression) or -70°C (multi-stage or cascade compression)

- Temperature ramp rate = 1-2°C/min with load (standard); high performance models achieve up to 15°C/min

- Offers reliable continuous operation with no ancillary services required

- Ideal for testing electronic assemblies with higher heat dissipation

Standard Models

| Internal Size (mm) | Type | External Size (mm) | Temp Range | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | W | D | H | Ltrs | W | D | H | Max | Min |

| TC Cyclone 600 800 -40 ME | 600 | 800 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -40 |

| TC Cyclone 600 800 -70 ME | 600 | 800 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -70 |

| TC Cyclone 1000 -40 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -40 |

| TC Cyclone 1000 - 70 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -70 |

| TC Cyclone 1500 1000 -40 ME | 1500 | 1000 | 1000 | 1500 | 2500 | 1540 | 2200 | 180 | -40 |

| TC Cyclone 1500 1000 70 ME | 1500 | 1000 | 1000 | 1500 | 2500 | 1540 | 2200 | 180 | -70 |

| TC Cyclone 2000 1500 1000 -40 ME* | 2000 | 1000 | 1500 | 3000 | 3230 | 1550 | 2300 | 180 | -40 |

| TC Cyclone 2000 1500 1000 70 ME* | 2000 | 1000 | 1500 | 3000 | 3230 | 1550 | 2300 | 180 | -70 |

| with remote cooling plant only | |||||||||

High Performance Models (Cyclone-S)

| Internal Size (mm) | Type | External Size (mm) | Temp Range | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | W | D | H | Ltrs | W | D | H | Max | Min | TC Cyclone- -S 600-40 ME | 600 | 600 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -40 |

| TC Cyclone-S 600-70 ME | 600 | 600 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -70 |

| TC Cyclone- -S 1000-40 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -40 |

| TC Cyclone-S 1000-70 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -70 |

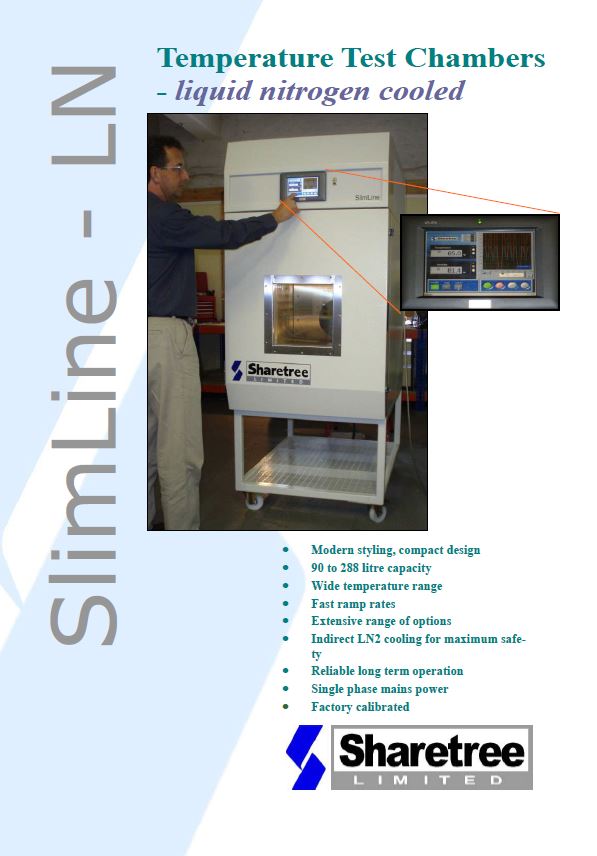

Direct Liquid Nitrogen (LN2) Cooling (Stressmaster Chambers)

- Range of LN2-cooled chambers with same dimensions and volumes as standard model range above

- Liquid nitrogen injected directly into the chamber to rapidly cool the interior

- Maximum temperature = +250°C; minimum temperature = -70°C

- Temperature ramp rates up to 60°C/min

- Ideal for thermal shocking of materials in accelerated life testing

- Requires continuous supply of LN2 and safe venting of nitrogen gas during operation

- Caution – reduced oxygen levels can occur inside the chamber

| Internal Size (mm) | Type | External Size (mm) | Temp Range | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | W | D | H | Ltrs | W | D | H | Max | Min | TC Cyclone- -S 600-40 ME | 600 | 600 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -40 |

| TC Cyclone-S 600-70 ME | 600 | 600 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -70 |

| TC Cyclone- -S 1000-40 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -40 |

| TC Cyclone-S 1000-70 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -70 |

Forced Ambient Air Cooling

- Range of heat-only chambers (ovens) with same dimensions and volumes as ranges above (model numbering TC Slimline 300 FAC, etc)

- Controlled cooling to avoid thermal shocking of components under test

- Maximum temperature = +250°C; minimum temperature = ambient + 20°C

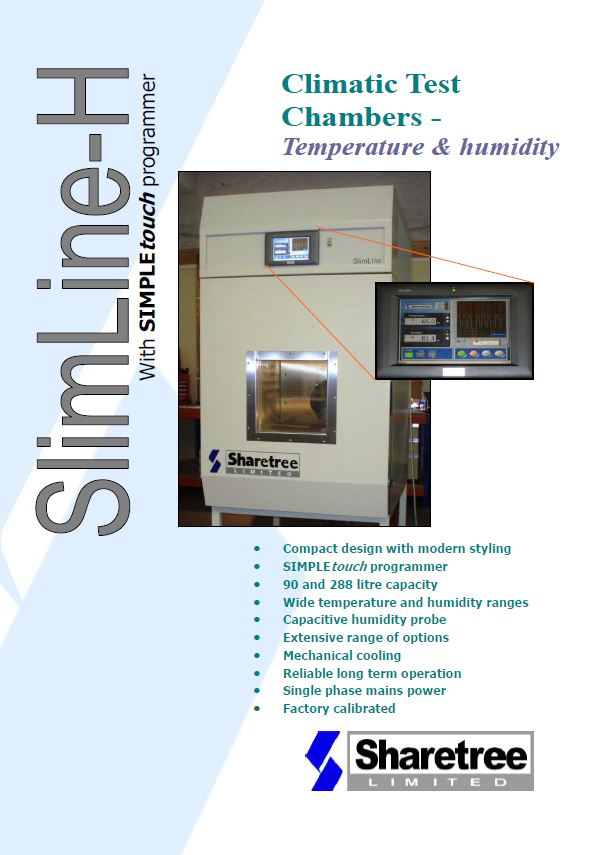

Cyclone Environmental Chambers

Combine temperature cycling with precise control of the relative humidity.

- Same cooling mechanism, temperature ranges and ramp rates as compressor-cooled thermal chambers

- Maximum temperature = +180°C; minimum temperatures = -40°C (single-stage compression) or -70°C (multi-stage or cascade compression)

- Water vapour added to air from heated water bath and removed through condensation on cooled copper coil

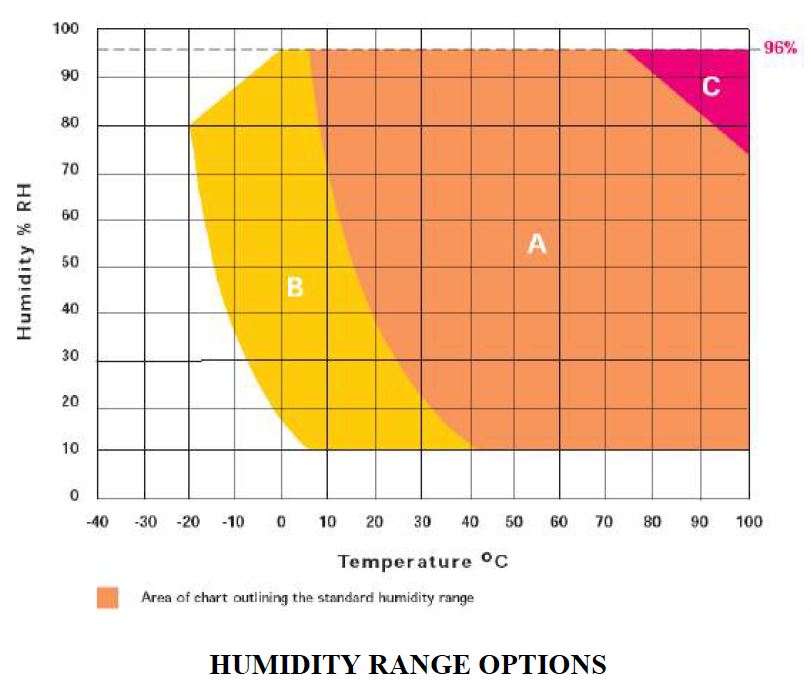

- As standard, achieves humidity conditions within region A in chart below; can be modified to meet regions B and C if required (amend model number to TH(AB)C/TH(AC)C/TH(ABC)C as appropriate)

Standard Models

| Internal Size (mm) | Type | External Size (mm) | Temp Range | Humidity Range | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | W | D | H | Ltrs | W | D | H | Max | Min | %RH | |

| TC Cyclone 600 800 -40 ME | 600 | 800 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -40 | Area 'A' | |

| TC Cyclone 600 800 -70 ME | 600 | 800 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -70 | Area 'A' | |

| TC Cyclone 1000 -40 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -40 | Area 'A' | |

| TC Cyclone 1000 - 70 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -70 | Area 'A' | |

| TC Cyclone 1500 1000 -40 ME | 1500 | 1000 | 1000 | 1500 | 2500 | 1540 | 2200 | 180 | -40 | Area 'A' | |

| TC Cyclone 1500 1000 70 ME | 1500 | 1000 | 1000 | 1500 | 2500 | 1540 | 2200 | 180 | -70 | Area 'A' | |

| TC Cyclone 2000 1500 1000 -40 ME* | 2000 | 1000 | 1500 | 3000 | 3230 | 1550 | 2300 | 180 | -40 | Area 'A' | |

| TC Cyclone 2000 1500 1000 70 ME* | 2000 | 1000 | 1500 | 3000 | 3230 | 1550 | 2300 | 180 | -70 | Area 'A' | |

| with remote cooling plant only | |||||||||||

High Performance Models

| Internal Size (mm) | Type | External Size (mm) | Temp Range | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | W | D | H | Ltrs | W | D | H | Max | Min | TC Cyclone- -S 600-40 ME | 600 | 600 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -40 |

| TC Cyclone-S 600-70 ME | 600 | 600 | 600 | 216 | 1560 | 1230 | 1810 | 180 | -70 |

| TC Cyclone- -S 1000-40 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -40 |

| TC Cyclone-S 1000-70 ME | 1000 | 1000 | 1000 | 1000 | 2000 | 1540 | 2200 | 180 | -70 |

Humidity – Standard Operating Regions

Cyclone-V Vibration Testing Systems

- Combines vibration testing with temperature cycling to meet AGREE test requirements

- Components under test connect to vibration tester through silicone gasket in floor of chamber

- Replace gasket with steel panel (supplied) to return chamber to normal operation