Fume cupboards (also known as fume hoods) are an essential part of almost any laboratory, as they allow chemical or biological substances to be handled without causing exposure to the operator. They provide an enclosed workspace through which an airflow is drawn continuously from front to back, carrying any fumes or dusts away from the worker and out through a rear duct. Depending on the substances being handled, this air can then be passed through suitable decontamination processes before being vented to the atmosphere.

Most environmental test chambers are too large to fit inside standard fume cupboards, meaning that there is a risk of exposure when transferring materials between the fume cupboard and the chamber. Sharetree was requested by a client to develop a chamber specifically for use in a fume cupboard, so that hazardous samples could be tested without compromising the protection of workers.

One unanswered question when starting this work was: is it possible for a fume cupboard and an environmental chamber to both work as they should when integrated in this ‘Russian doll’ arrangement? The performance of a fume cupboard is strongly affected by the amount of equipment within it and the proximity of items to the front of the cupboard, where the air is drawn in under a sash window. The critical aspect of this work was that neither component must adversely affect the performance of the other.

Keeping the air flowing

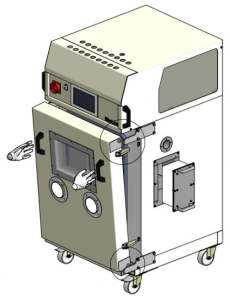

Fortunately, there was already an excellent starting point available—Sharetree’s Slimline range of chambers, which have been designed specifically for space-critical applications in test houses, with capacities that would be suitable for accommodating the product quantities manufactured in a laboratory.

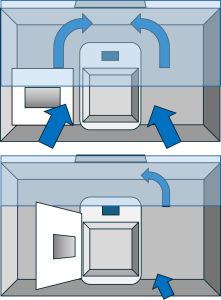

The most important modification made to the standard design was to replace the hinged front door with one that could be clipped in place and then completely removed. Without this, the sash window would need to be raised to a much greater height when working inside the chamber, and the air flow from one side of the chamber would be completely blocked, as shown in the diagrams below.

Once installed in the fume cupboard, it was clear that the normal location of the SIMPLEtouch control panel on the front of the chamber was not ideal, as operating it would require the sash window of the fume cupboard to be raised considerably, again reducing that all-important air flow. However, the SIMPLEtouch panel is equipped with a TCP-IP (LAN) Modbus interface which allowed the screen’s contents to be viewed and operated via a remote desktop outside the fume cupboard, avoiding the need to move the sash window at all.

Tests of the modified chamber in situ showed that not only did the fume cupboard maintain the rate of air extraction required by COSHH, but that the temperature control inside the chamber was not compromised by the fact that it was sitting inside an external stream of air.

Although in this instance the chamber was not required to have any active extraction of its own, this would be straightforward to incorporate into the design and integrate with the fume cupboard’s extraction system.