Test Chambers for Heat Pumps

As countries look to integrate renewable sources of energy into their national electricity grids, heat pumps continue to gain acceptance in many regions as a viable means of controlling indoor temperatures.

Testing of these systems, though complex, is essential to accurately measure a product’s coefficient of performance (COP) and help purchasers make an informed choice. These tests rely on a tightly controlled and stable environment in which the heat pump can operate.

SIMPLEtouch

Touch Screen Programmer

Easy set-up and monitoring of chamber conditions, simplifies programming of complex cycles… read more

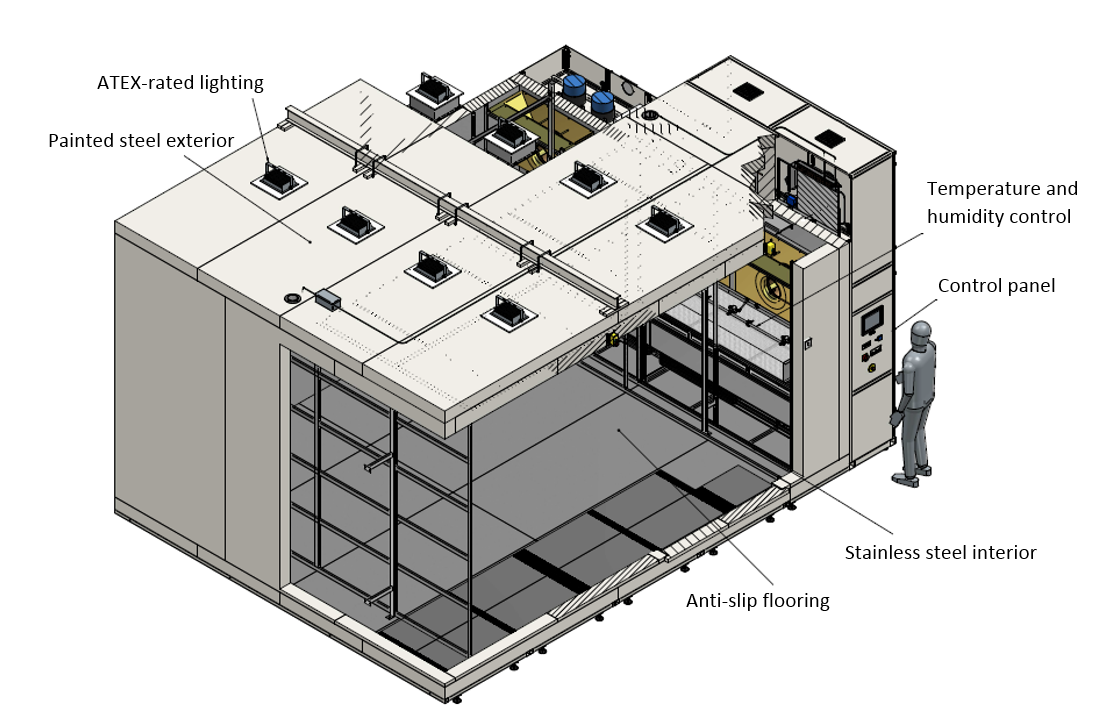

Sharetree’s range of walk-in chambers can provide the test environment required by a whole range of standards for air-source heat pumps, such as EN 14511 and EN 16147:

- The chamber delivers a gentle, laminar air flow with accurate and precise control of temperature and relative humidity.

- The heat pump takes in this air and extracts its thermal energy.

- This energy is transferred to a water or space heating system and the results are measured to calculate the COP.

Possible testing configurations include:

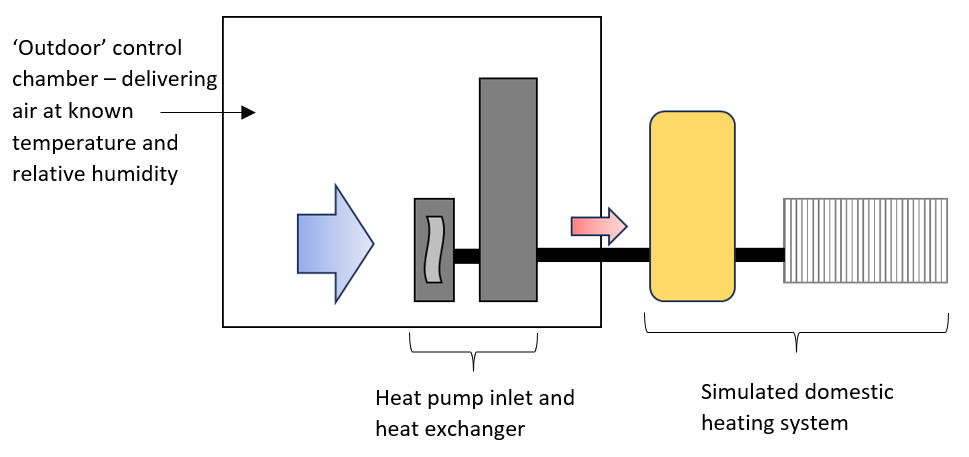

Single chambers for testing air-to-water heat pumps (for domestic hot water and central heating systems)

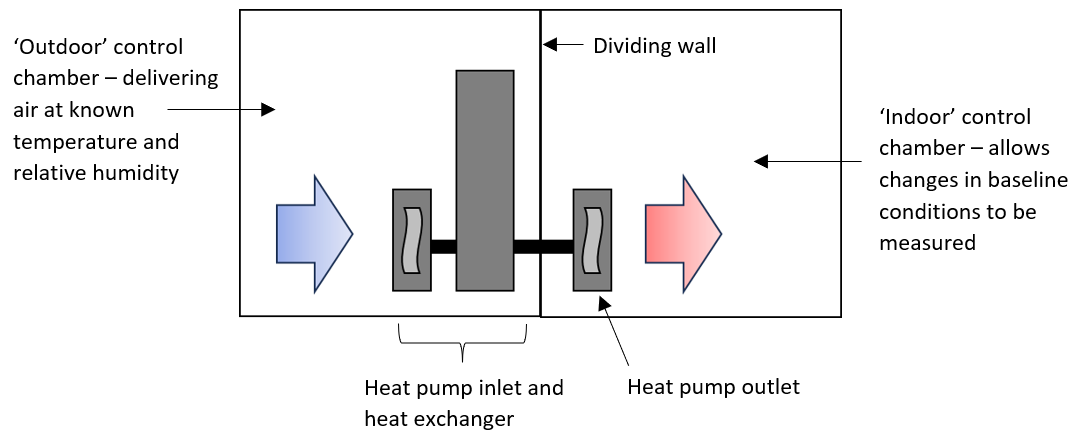

Split chambers for testing air-to-air heat pumps (used in smaller properties such as apartments)

| Benefit | Achieved by |

|---|---|

| High performance | Laminar air flow (adjustable down to <1.5 m/s) from left to right across the chamber – maintains uniform and stable conditions throughout the internal space |

| Combination of dried air and demineralised water spray used to control relative humidity at a range of temperatures to simulate different weather conditions (e.g. | |

| PT100 sensors for stable and reliable temperature measurement | |

| Capacitive humidity sensor gives optimum combination of accuracy, rapid response and reliability | |

| Chambers built from high quality components ensuring long service lifetimes | |

| Test conditions rapidly established following system start; fast recovery from defrosting cycles (usually within 10 minutes) | |

| Customisable | Wide range of volumes and dimensions available, with high ceilings to avoid heat pump recycling its exhaust air |

| Designed following site visit to maximise use of space in your facilities | |

| Environmental control systems can be tailored to meet minimum temperature, cooling rates and relative humidity requirements | |

| Extensive range of port and panel options available for interfacing with systems under test (for passing liquids, power cables, data communications, etc.) | |

| Labview-based user interface developed by Sharetree, subscription-free and easily customised | |

| Safe to use | Essential safety features included as standard: • emergency pull cords • internal door release • slip-resistant flooring |

| Option for ATEX-rated internal volumes for testing systems that contain propane-based refrigerants | |

| Detection system for multiple gases (including oxygen depletion) and infrared fire detection | |

| Easy to use and maintain | Factory-calibrated and expertly installed for you by Sharetree |

| Uses readily available components for long-term maintainability | |

| PC-based touchscreen control panel – connects to industry standard PID controller that is readily maintained or replaced, minimising downtime |

| Key Specifications (typical values) | ||

|---|---|---|

| Temperature fluctuation | ± 0.5 | °C |

| Temperature range (unloaded) | -40 to +60 | °C |

| Temperature range with load (optimised to meet specification) | -22 to +50 | °C |

| Ramp rate to -22°C with load | 0.5 | °C/min |

| Maximum cooling load | 20 | kW |

| Maximum mass of load (distributed) | 1500 | kg |

| Parameters above are for standard models; for information on customised system performance, please contact Sharetree. | ||

Chamber features