Controlling the moisture content of products can often be critical to ensuring that they meet their specifications. It’s not only the final percentage of water that is of importance; the speed at which the product is conditioned can also be a factor. This is especially relevant in foodstuffs, where texture and other physical characteristics are often affected by the rate of either drying or humidifying.

The conditions needed for rapid removal of moisture, such as infrared drying using radiant heaters, can sometimes be too extreme and cause damage to products; slower drying over time periods of around 12 hours is often needed in these cases. This time factor can make the difference between a product passing or failing its quality control tests.

However, the time needed to condition products cannot prevent a manufacturing process from being economical. A degree of flexibility is needed to help manage peaks and troughs in demand. So when Sharetree engineers were requested to produce a large chamber which would give repeatable drying performance of a bulk product regardless of the loading in the chamber, it tested their engineering ingenuity and their experience in developing chambers with precise environmental control.

Not too cold, not too dry

The client’s requirement was to dry ‘Gummy’ products, chewable vitamin supplements which have very tight specifications relating to their moisture content. They are very much a ‘Goldilocks’ product: the conditions need to be just right to ensure they have the texture and elasticity needed. The target of extracting 15 litres per hour of water from a fully loaded chamber was challenging, especially as more aggressive forms of drying had to be avoided. Furthermore, production planning required the flexibility to vary the chamber loading without affecting the drying characteristics of the process. This implied an air flow regime that would be consistent no matter what percentage of the chamber was occupied.

Sharetree’s engineers quickly realised that water removal using dry air or low temperatures alone would not be sufficient – the required volumes of dry air would be excessive, and the use of refrigerated air could cause bound water in the product to freeze, affecting the material properties and slowing down drying yet further. A combination of the two was determined to offer the best prospect of success, and eventually a target was selected: a controllable humidity in the range of 10-20%, under drying temperatures of 20-50°C.

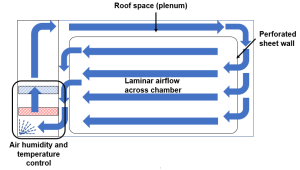

The chamber was equipped with a cooling system and a large desiccant air drier to achieve the required temperature and humidity for optimum water extraction. The critical issue of reproducible air flow was tackled by creating a laminar regime within the chamber, by pushing the conditioned air through a plenum (roof space) to the far end of the chamber and then using fans to draw it back across the space through a wall made of perforated sheets.

To ensure that the carefully controlled conditions inside the chamber would not be disrupted every time the door was opened to add or remove product, the walk-in chamber had a small anteroom added. This acted as a buffer zone between the chamber and the ambient conditions of the production area.

Field testing of the chamber proved that it met the client’s specifications for drying rate under various loadings, and was subsequently integrated into their manufacturing process, allowing the chewable vitamins to remain deliciously chewy! Sharetree anticipates that these types of chamber will be suitable for many other demanding drying applications.