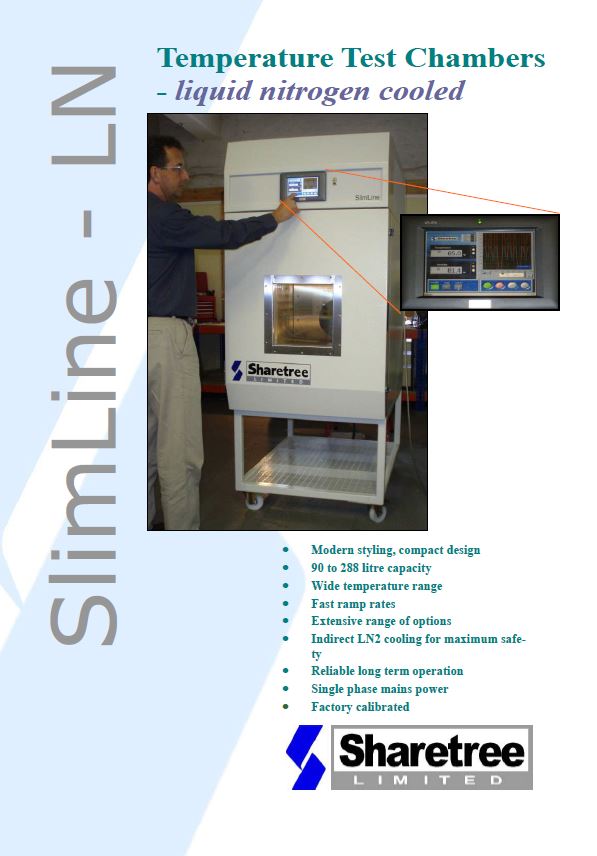

RampMaster Range

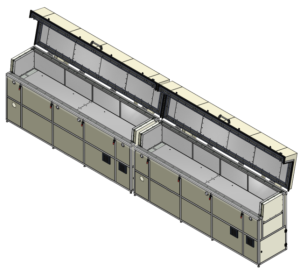

Test long, thin products with optimum chamber footprint

Typical Applications

- Life testing of electronic components (including powered cycling)

- Temperature testing under fixed or cyclic conditions, satisfying numerous IEC 60068 test requirements plus a wide range of equivalent specifications

- Originally designed for temperature testing of tools and probes for use in oil and gas wells, where vibration and magnetic fields must often be minimised during testing

SIMPLEtouch

Touch Screen Programmer

Easy set-up and monitoring of chamber conditions, simplifies programming of complex cycles… read more

| Benefit | Achieved by |

|---|---|

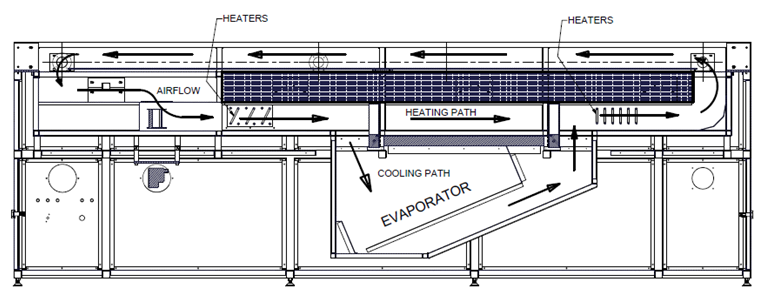

| High performance under load | Powerful circulating fans ensure low thermal gradients around the test items, giving reliable and reproducible results |

| PT100 sensor for stable and reliable temperature measurement | |

| Air flow down the length of the chamber avoids thermal shocking of components (often seen with cross-axis air flow) | |

| Sensitive instrumentation can be isolated from vibration and magnetic fields for accurate measurements | |

| Chambers built from high quality components ensuring long service lifetimes | |

| Thermal insulation and heat breaks minimise operating costs | |

| Customisable | Wide range of lengths available (from 2 metres up to 8 metres with conjoined chambers) |

| Environmental control systems can be tailored to meet temperature and cooling rate requirements | |

| Optional Labview-based user interface developed by Sharetree and easy to upgrade and customise | |

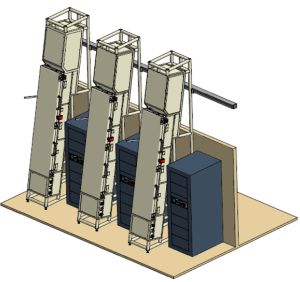

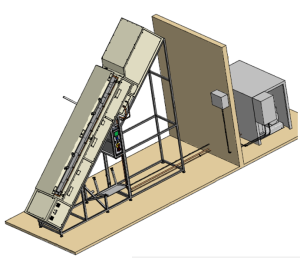

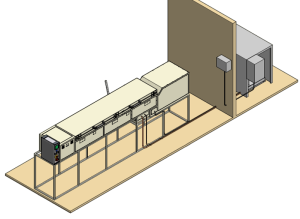

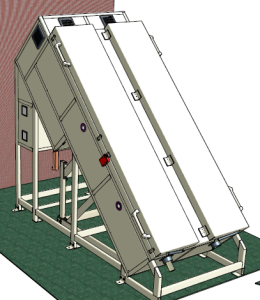

| Variety of configurations available (horizontal, vertical, inclined at 45°, twin bays, conjoined) | |

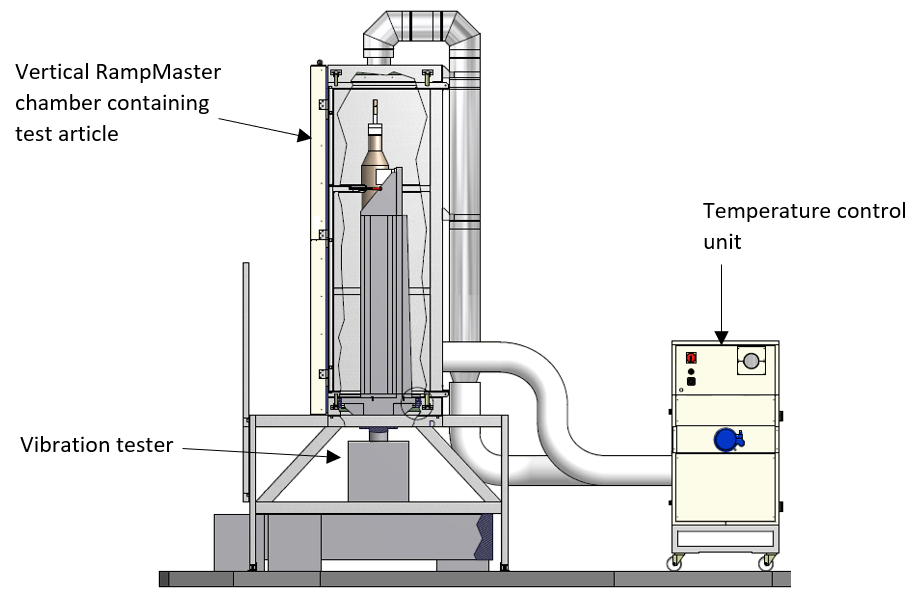

| Models available that combine vibration and temperature testing | |

| Customised jigs for holding or rotating items under test | |

| Easy to use and maintain | Factory-calibrated and expertly installed for you by Sharetree |

| Uses readily available components | |

| Ports available for connecting electrical, pneumatic or hydraulic systems to products under test | |

| L-shaped powered door options for easier access to chamber and test items | |

| PC-based touchscreen control panel – connects to industry standard PID controller that is readily maintained or replaced, minimising downtime [link to separate content on controller] |

Configuration Options

Temperature Control

Heating

Electrical heaters are used to supplement the power dissipation of the items under test in order to improve temperature control and increase heating rates. Solid-state switching minimises transients and switching noise.

Cooling

Choose from three different cooling mechanisms depending on your requirements.

| Type of cooling | How it works | Features | Temperatures |

|---|---|---|---|

| Forced ambient air | Air is blown directly into the chamber from the external atmosphere |

• Lower cost option when sub-ambient temperatures not required

• Can cool from high temperatures |

Ambient + 20°C to 250°C |

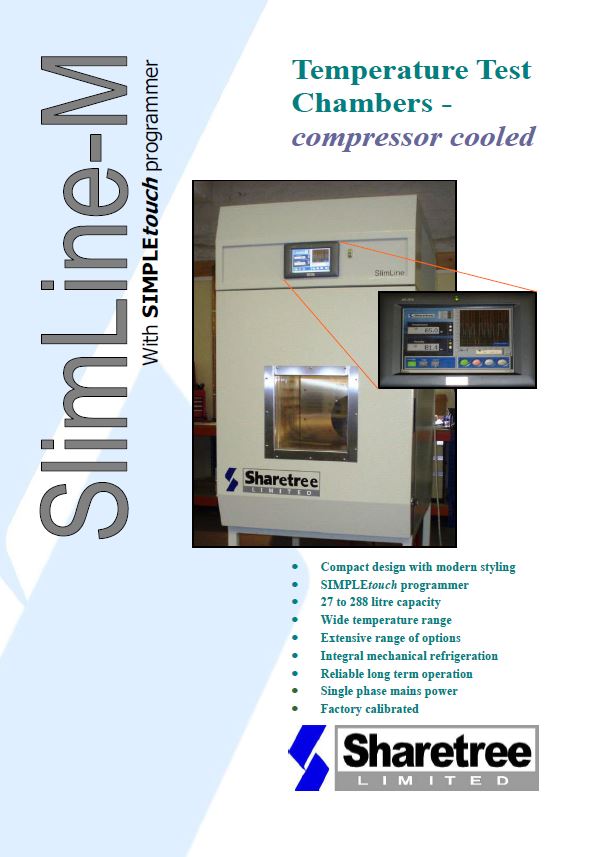

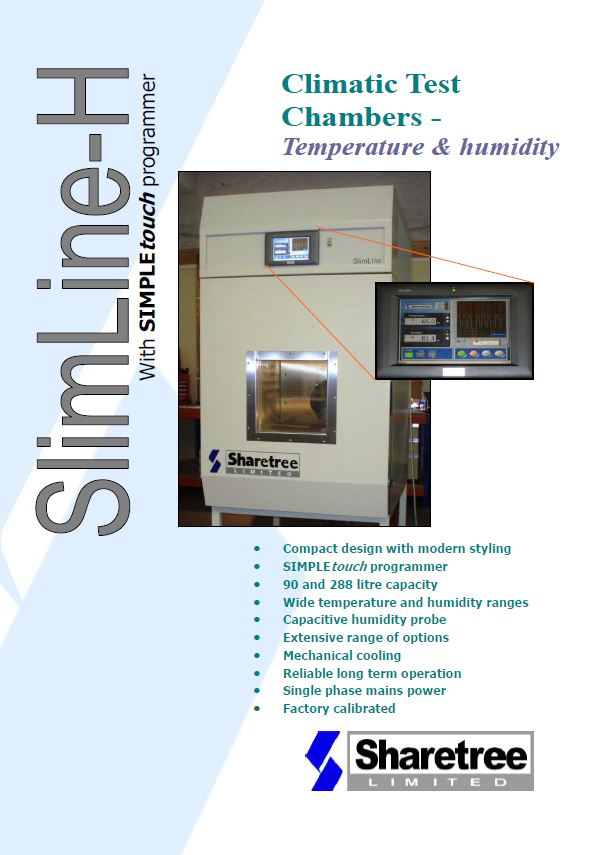

| Compressor | Refrigerant gases in a closed-loop system are repeatedly compressed and expanded to cool the air in the chamber (same principle as domestic refrigerators) |

• Less costly method of active cooling than cryogenic system, with no ancillary services required

• More complex than forced air cooling

• Can cool from high temperatures using Evaporator Protection* |

• Single stage: -40°C to 180°C

• Multi-stage or cascade: -60°C to 180°C • Can heat to 200°C for up to 4 hours • Maximum increases to 250°C with Evaporator Protection* |

| Cryogenic (liquid nitrogen) | Liquid nitrogen is injected directly into the chamber to rapidly cool the interior |

• Faster cooling rates than compressor cooling (up to 10°C/min)

• Requires continuous supply of LN2 and safe venting of nitrogen gas during operation |

-70°C to 200°C |

| * Proprietary design where the chamber switches from compressor cooling to forced air cooling above 150°C to avoid thermal damage to the refrigerant in the cooling coil (shown below). | |||

Vibration Testing Systems

• Combines vibration testing with temperature cycling to meet AGREE test requirements

• Components under test connect to vibration tester through silicone gasket in floor of chamber