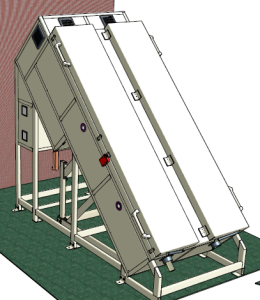

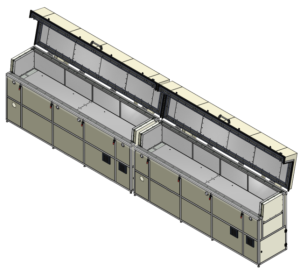

RampMaster Range

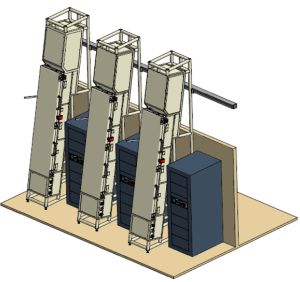

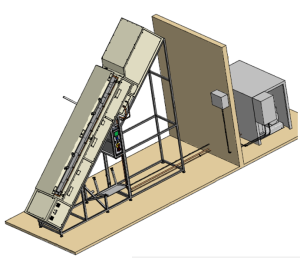

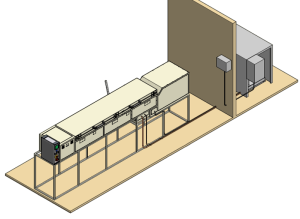

Test long, thin products with optimum chamber footprint

Typical Applications

- Life testing of electronic components (including powered cycling)

- Temperature testing under fixed or cyclic conditions, satisfying numerous IEC 60068 test requirements plus a wide range of equivalent specifications

- Originally designed for temperature testing of tools and probes for use in oil and gas wells, where vibration and magnetic fields must often be minimised during testing

Advantages

Wide Range of Internal Sizes

Internal sizes from 218ltrs to 3000ltrs, to suit your requirement, as well as custom internal size, if required.Wide Temperature and Humidity Ranges

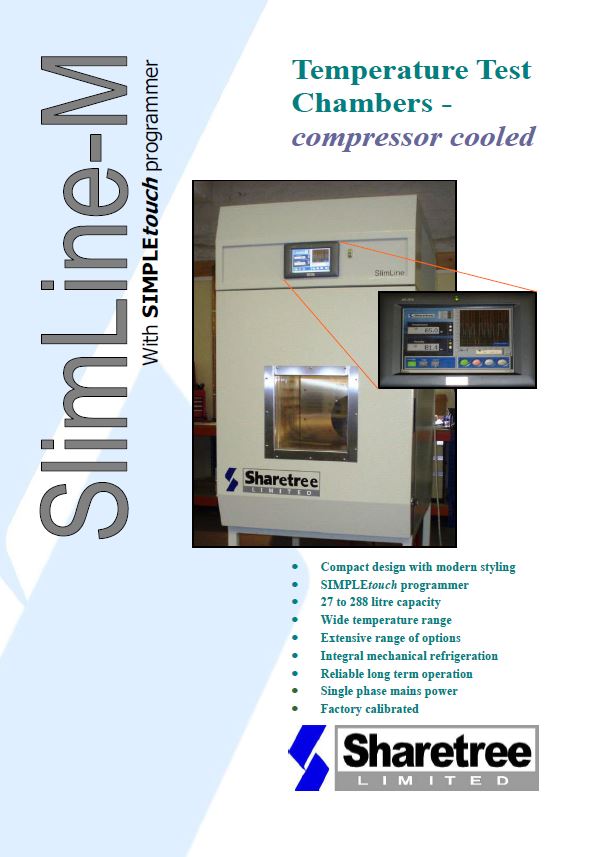

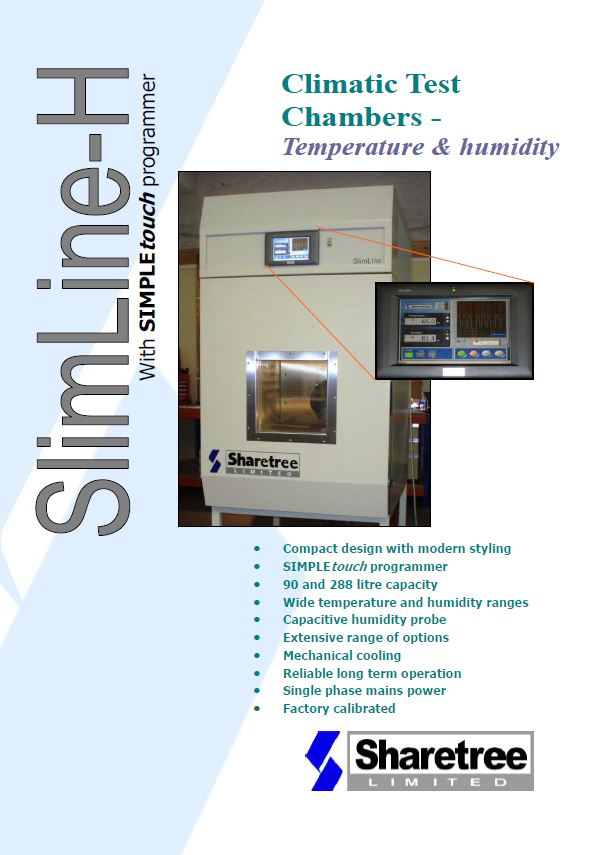

Temperature ranges of +180°C to either -40°C or -70°C are available and even +250°C with our Evaporator Protection feature. Liquid Nitrogen chambers are available with ranges up to +250°C to -100°C. Mechanically cooled chambers can be fitted with humidity covering all areas (10% to 98%RH, 10 to 100°C)High Performance even under Load

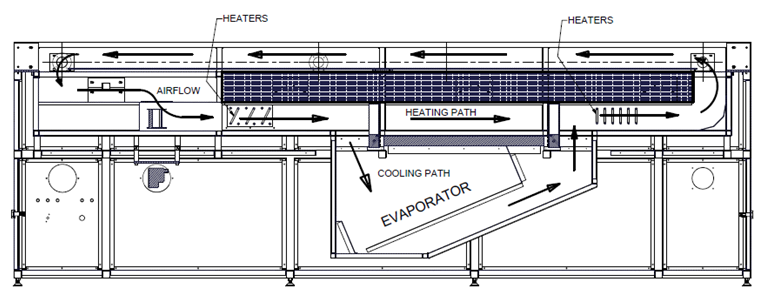

Cyclone chambers have a high laminar airflow, providing excellent thermal performance over the whole interior of the chamber, even under densely packed conditions. In addition, the thermal plants are sized to perform under loaded conditions.SIMPLEtouch Programmer

All chambers fitted as standard with our latest SIMPLEtouch programmer for ease of use and a host of features, including remote monitoring &/or control of the chamber using an industry standard MODbus interface.Capacitive Humidity Probe

No maintenance capacitive probes fitted as standard on the temperature/humidity models.Extensive range of Options

Including windows, standard and specially designed ports, product rotation systems, dry-air or N2 feeds, LN2 Boost cooling, glove ports, safety interlock on door, and much more.Suitable for Testing most Standards

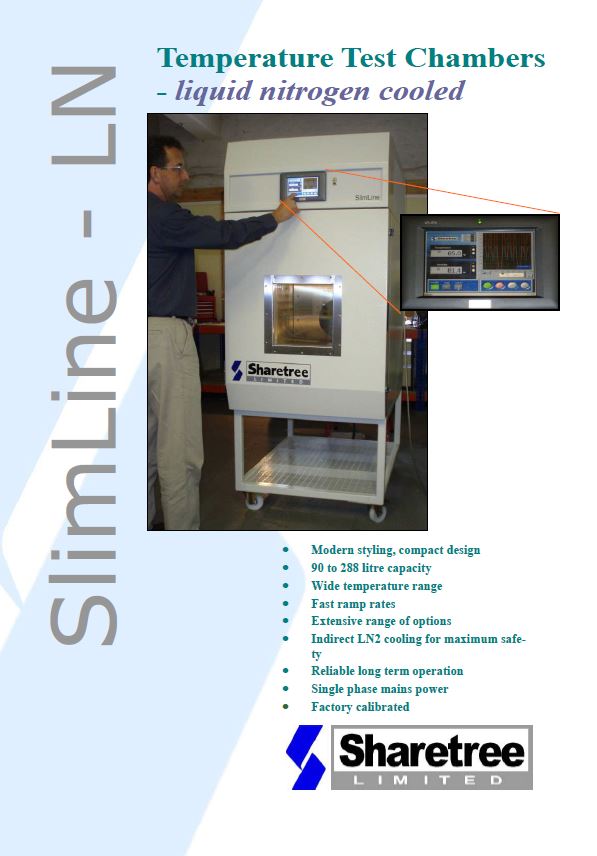

Suitable for testing most environmental standards such as IEC 60068, etc.SIMPLEtouch

Touch Screen Programmer

Easy set-up and monitoring of chamber conditions, simplifies programming of complex cycles… read more

Configuration Options

Temperature Control

Heating

Electrical heaters are used to supplement the power dissipation of the items under test in order to improve temperature control and increase heating rates. Solid-state switching minimises transients and switching noise.

Cooling

Choose from three different cooling mechanisms depending on your requirements.

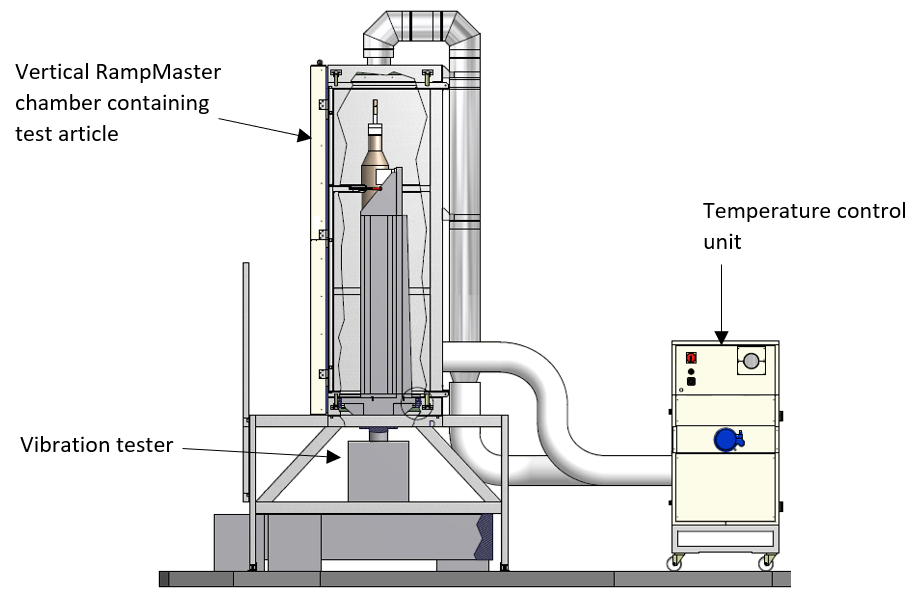

Vibration Testing Systems

• Combines vibration testing with temperature cycling to meet AGREE test requirements

• Components under test connect to vibration tester through silicone gasket in floor of chamber