Walk-In / Drive In Rooms Range

Much more than an air-conditioned room

Typical Applications

- Temperature/humidity testing of large volumes of components under fixed or cyclic conditions

- Conditioning of raw materials, pharmaceutical products

- Testing of fully assembled automotive vehicles

- Testing of large components for use in hostile environments

SIMPLEtouch

Touch Screen Programmer

Easy set-up and monitoring of chamber conditions, simplifies programming of complex cycles… read more

| Benefit | Achieved by |

|---|---|

| High performance | Careful control of airflow generates stable conditions throughout the interior, even when fully loaded |

| PT100 sensor for stable and reliable temperature measurement | |

| Capacitive humidity sensor gives optimum combination of accuracy, rapid response and reliability | |

| Chambers built from high quality components ensuring long service lifetimes | |

| Cooling plant generously sized and mounted to minimise vibration and noise (or installed remotely if preferred) | |

| Customisable | Wide range of volumes and dimensions available |

| Designed following site visit to maximise use of space in your facilities | |

| Floors can be strengthened for testing vehicles or other heavy loads | |

| Environmental control systems can be tailored to meet minimum temperature, cooling rates and relative humidity requirements | |

| Option for ATEX-rated internal volumes for flammable or explosive test articles | |

| Services inside the chamber (e.g., electrical power sockets) are configured to suit your application | |

| Extensive range of port and panel options available for interfacing with articles under test | |

| Labview-based user interface developed by Sharetree, subscription-free and easily customised | |

| Safe to use | Essential safety features included as standard: emergency pull cords, internal door release, slip-resistant flooring |

| Optional gas detection available (oxygen, carbon dioxide) to ensure interior is safe to enter | |

| Easy to use and maintain | Factory-calibrated and expertly installed for you by Sharetree |

| Uses readily available components | |

| PC-based touchscreen control panel – connects to industry standard PID controller that is readily maintained or replaced, minimising downtime [link to separate content on controller] |

Modular Chambers

- Circulating or laminar airflow regimes available

- Maximum temperature = +80°C;

- Mminimum temperature = -40°C (single-stage compression) or -70°C (multi-stage or cascade compression)

- Temperature ramp rate = <5°C/min with load (depends on room volume)

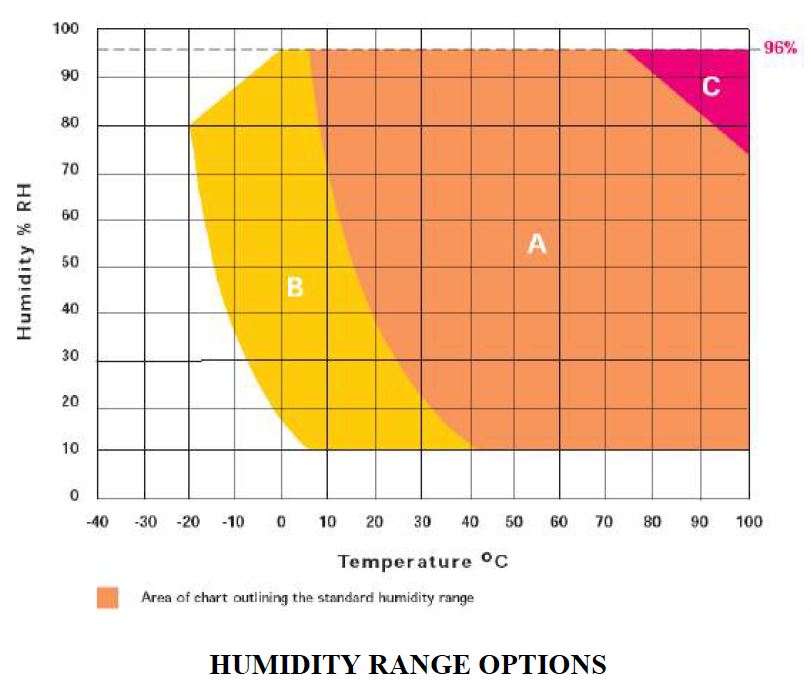

- Humidity generated using deionised water sprays (region A) or a combination of air driers and water sprays (regions B and C)

- Internal dimensions of up to 9 × 6 × 3 metres available, with flexible entrance dimensions

- Optional antechamber to preserve internal conditions during frequent entry/exit

- Built and tested at Sharetree, then dismantled, reassembled, and commissioned on site (reducing transport costs)

- Fully sealed and insulated to optimise energy usage

Single Piece Chambers

- Circulating or laminar airflow regimes available

- Maximum temperature = +150°C;

Mminimum temperature = -40°C (single-stage compression) or -70°C (multi-stage or cascade compression)

Temperature ramp rate = 1-5°C/min with load - Humidity generated using deionised water sprays (region A) or a combination of air driers and water sprays (regions B and C)

- Normally sent to site as built, so dimensions limited by transportation (max internal size 5 × 3 × 3 metres)

Airflow Control

If your application demands:

- temperature and/or humidity cycling

- large or variable loading densities

- highly stable conditions

then a small room equipped with a large HVAC system will not be capable of meeting your requirements and you will need to consider using an environmental chamber.

If stable environmental conditions are to be precisely maintained, then the airflow must be controlled carefully. There are two airflow regimes available in Sharetree’s chambers: circulating and laminar.

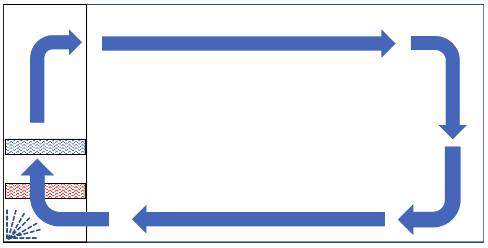

Circulating Airflow

- Simplest system to design and install

- Air passes around chamber from top to bottom

- Good control of temperature and humidity

- Ideal for less demanding test requirements and lower load densities

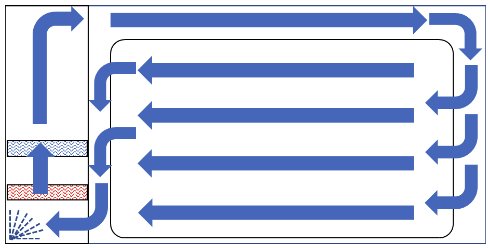

Laminar Airflow

- More complex design

- Air pulled across chamber evenly to give consistent conditions at all heights and locations

- Excellent control of temperature and humidity

- Adjustable louvres at one or both ends can give additional airflow control if needed

- Ideal for more demanding test requirements and higher load densities